Dr Florian Wallburg successfully defends his doctoral thesis on the production of silicon substrates

For his doctoral thesis "Experimental and numerical investigations into the damage behaviour of silicon substrates during the diamond wire sawing process" , HTWK graduate Florian Wallburg researched what happens during the production of silicon substrates, such as those required for solar cells. Among other things, his research findings are helping to make the production of solar modules even more reliable and efficient in the future.

Defence via livestream

Under corona-related access restrictions and in a digital livestream via YouTube, Florian Wallburg defended his doctoral thesis on 13 November 2020 at the TU Bergakademie Freiberg, Institute of Mechanics and Fluid Dynamics (IMFD). Several IMFD employees and the commission consisting of Prof Hans-Joachim Möller, Prof Alfons Ams and Prof Henning Zeidler (chairman of the commission) were present in person. The two reviewers, Prof. Meinhard Kuna from TU Freiberg and Prof. Stephan Schönfelder from the Faculty of Engineering at HTWK Leipzig, were digitally connected for the defence.

Wallburg's research work was carried out in cooperation with HTWK Leipzig, the Fraunhofer Centre for Silicon Photovoltaics Halle and TU Freiberg.

Research for the energy transition

Florian Wallburg's research focussed on ablation and damage processes during diamond wire sawing, the dominant manufacturing process for thin silicon substrates, also known as wafers. These form the basis for the production of solar cells. Silicon substrates are therefore essential for a successful energy transition.

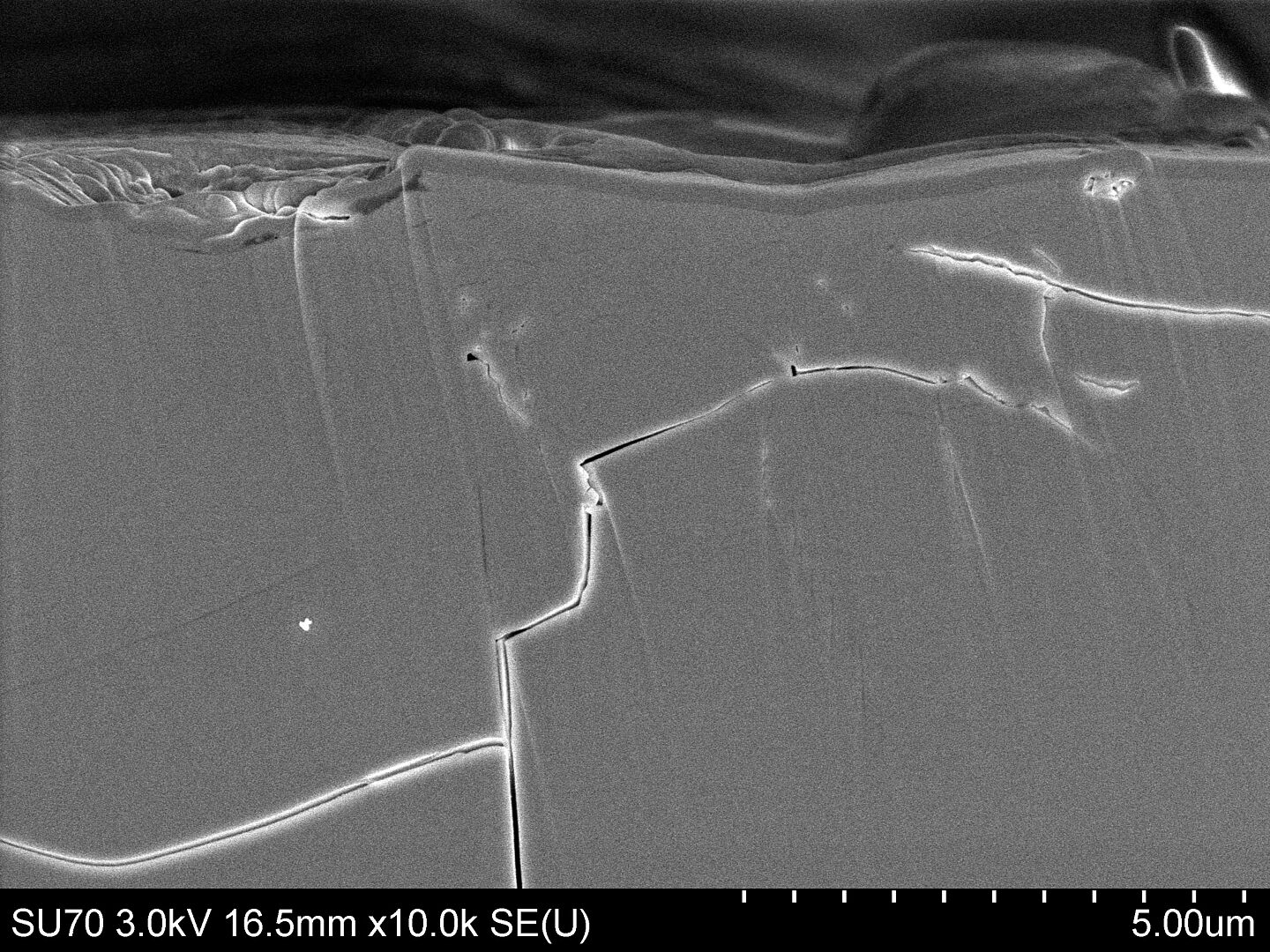

"In my work, I contribute to the understanding of the micromechanical damage and material removal mechanisms during the sawing process of these wafers, which is essential for the reliability of the manufacturing process and the quality of the finished products. This contribution is based on the development of a numerical model based on the finite element method, which has been validated with very many and very extensive experimental microstructure analyses and can thus contribute to the optimisation of the sawing process in the future," explains Dr Florian Wallburg.

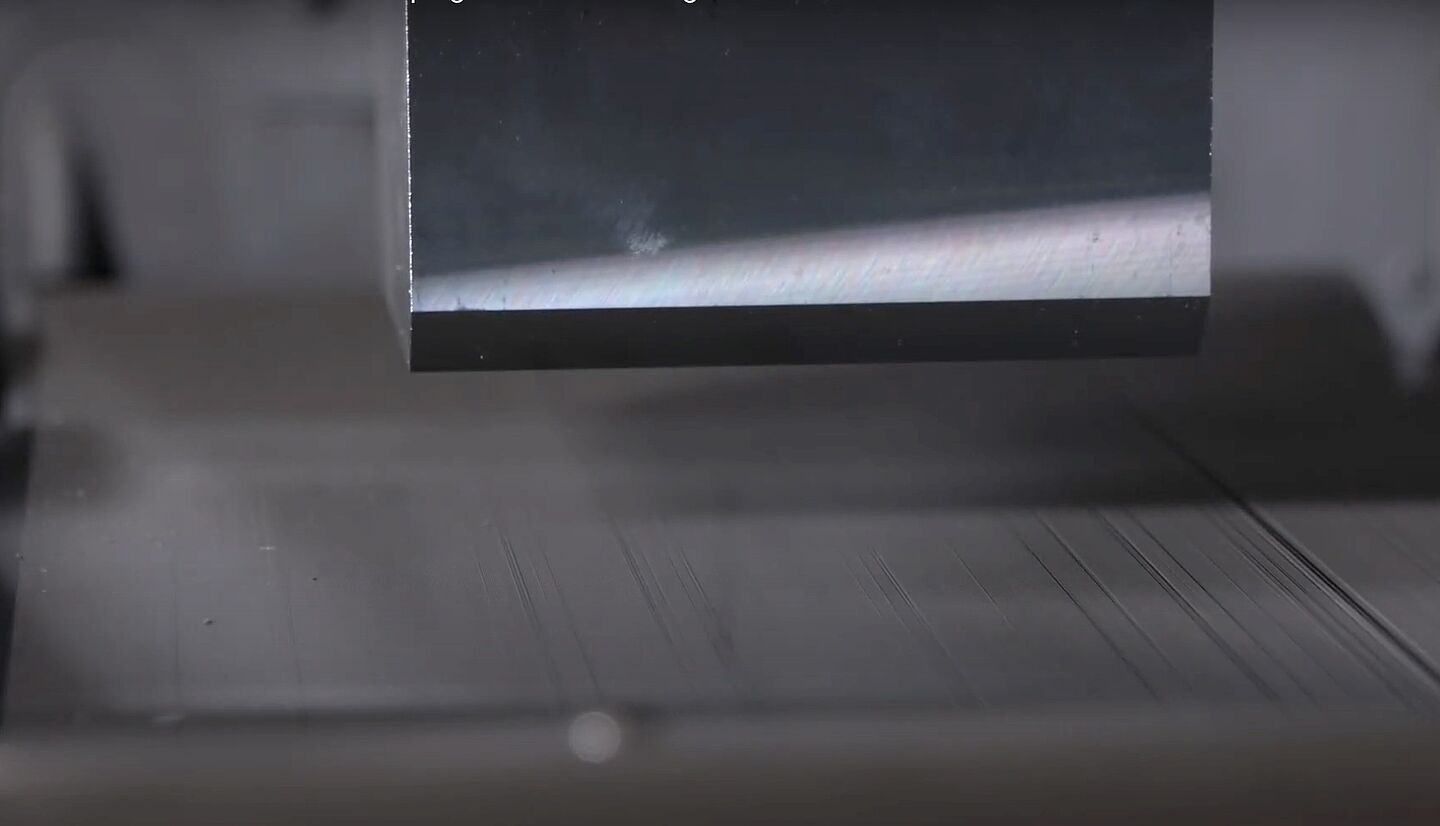

"In diamond wire sawing, a large silicon brick, i.e. a large piece of very pure silicon from which the wafers are later sawn, is pressed through a rotating wire field. As the process name suggests, the wires are studded with diamonds. These grind across the surface and thus lead to material removal," says Dr Wallburg.

"Diamond wire sawing works with the help of many wires next to each other, just like the egg cutter principle, except that the wire also moves."

"Figure 2 shows typical damage to a wafer (side view), as occurs when sawing with diamond wires. This is precisely what we need to avoid in future by optimising our manufacturing processes," explains Dr Florian Wallburg.

And what does the future hold?

Dr Florian Wallburg would like to continue working in research, especially application-oriented research. He is currently leading the interdisciplinary junior research group SmartKMU, which deals with digitalisation and the requirements of Industry 4.0 applications in small and medium-sized enterprises (SMEs).

SmartKMU explores the central question of how digitisation can be efficiently designed along the product development process with the help of smart simulation tools in order to quickly integrate the competitive advantages of digitised process chains into the day-to-day business of SMEs with their often limited digital infrastructures.