RecyRotor project: Scanning and separation process for the reuse of wind turbine rotor blade structures is being developed

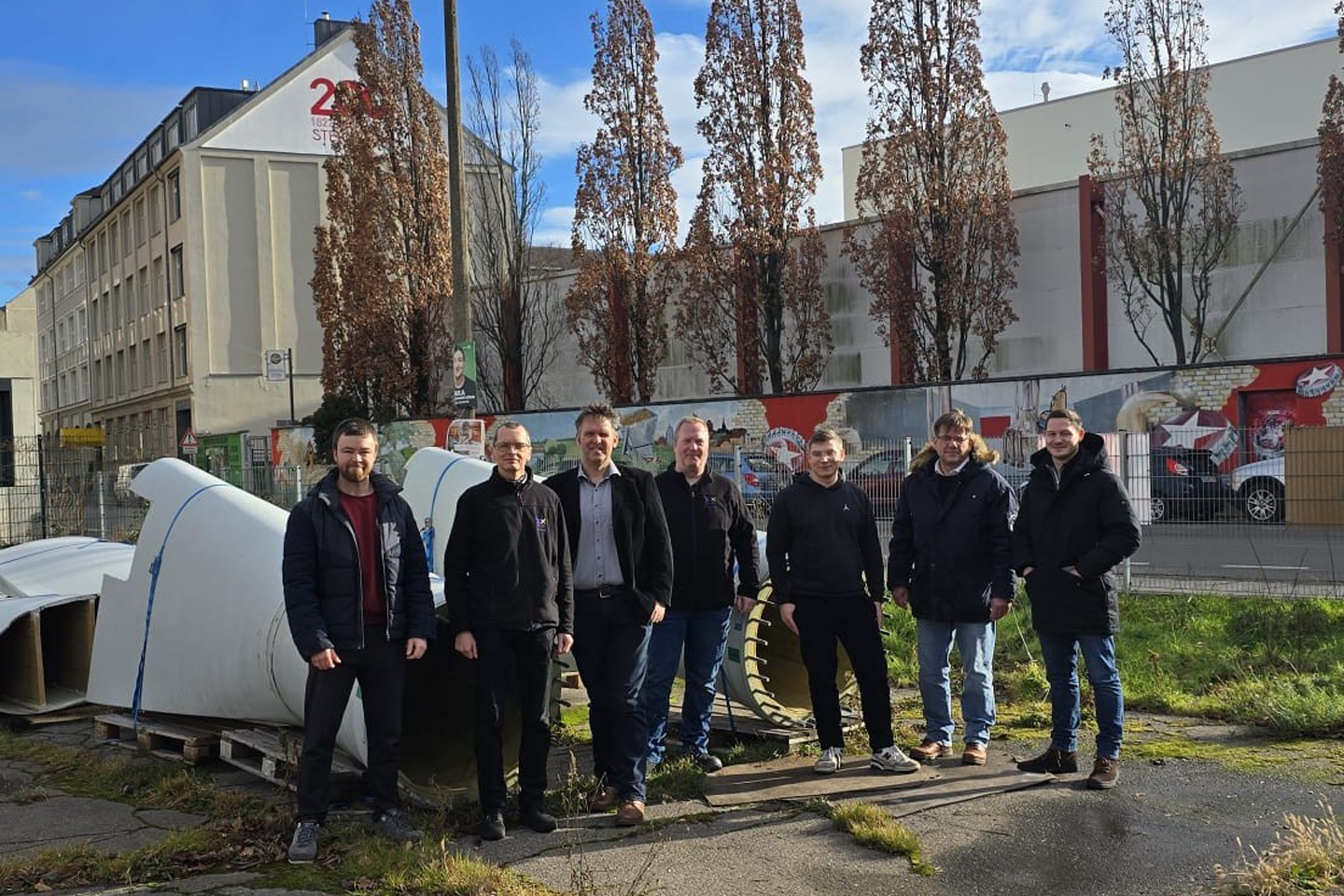

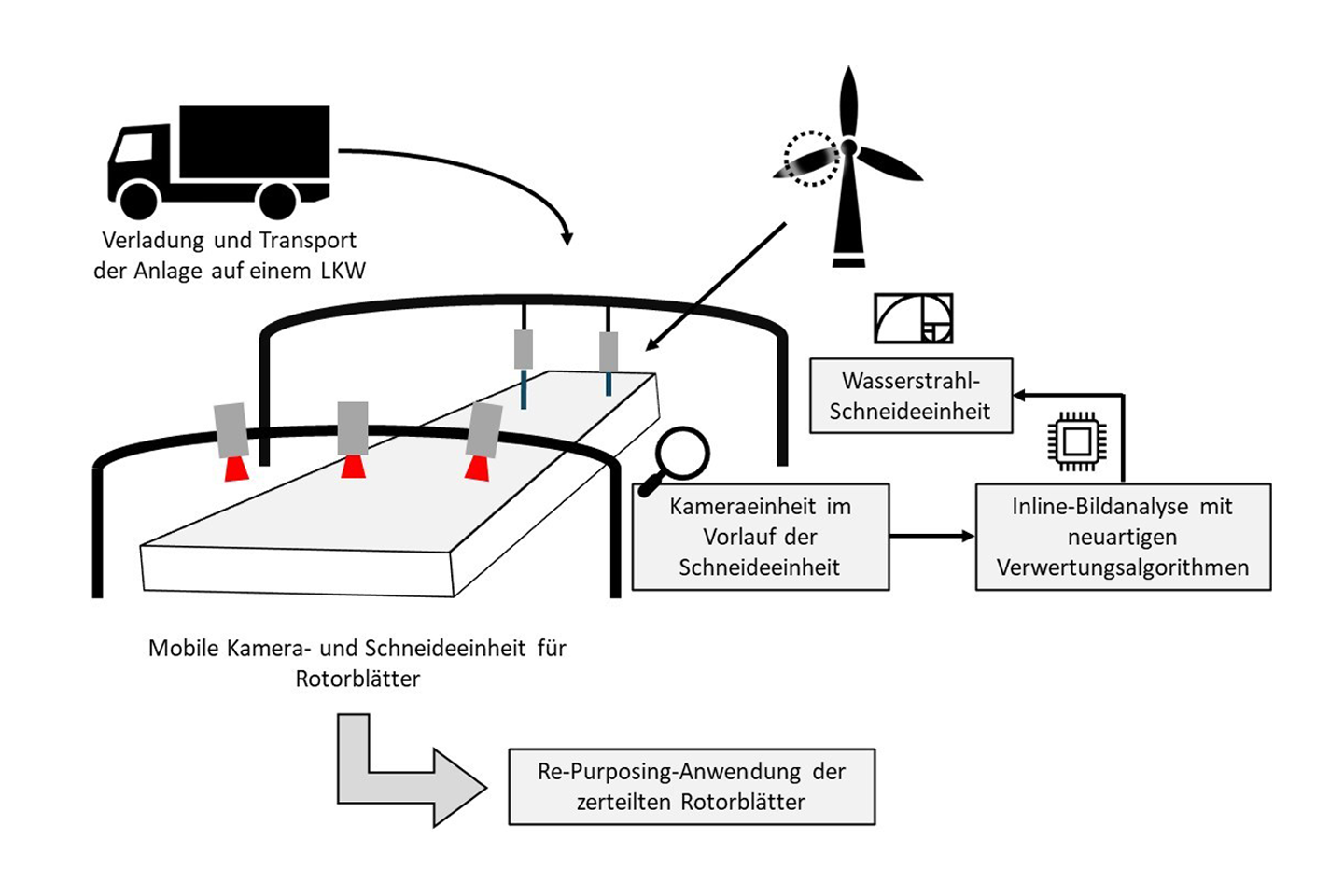

On 29 January 2025, the Composite Circularity Lab (CCL) at HTWK Leipzig hosted the kick-off meeting for a new application-oriented research project called "RecyRotor " for the reuse of previously used wind turbine rotor blade structures. The ZIM project, which was launched on 1 January 2025, is being carried out by the HTWK's lightweight construction research group in cooperation with the companies Herion Engineering GmbH (Taufkirchen) and Zertrox GmbH & Co KG (Aachen). The aim of the project is to develop market-ready processes for the diagnosis, evaluation and cutting of discarded wind turbine rotor blades on site at the wind farm. The aim is to separate subcomponents that are suitable for repurposing directly from those that need to be recycled.

"We hope that the technology focused on in RecyRotor will increase efficiency in the reuse of large fibre composite structures. Logistics, in particular the high cost of transporting the large rotor blades from the wind farm to a processing site, is often the critical point that still stands in the way of recycling the materials in the sense of the circular economy. The RecyRotor process will eliminate this disadvantage in the foreseeable future," explains project manager Prof Robert Böhm. "We are delighted to have gained two of Germany's leading specialists in the fields of cutting technology and image recognition for the project: Herion Engineering GmbH and Zertrox GmbH. This collaboration will give further impetus to repurpose technology, which has been gradually developed to series maturity at the HTWK over the past four years," predicts CCL Director Philipp Johst. The project will run until June 2027 and will be carried out in the CCL Lab on the Eilenburger Straße campus.