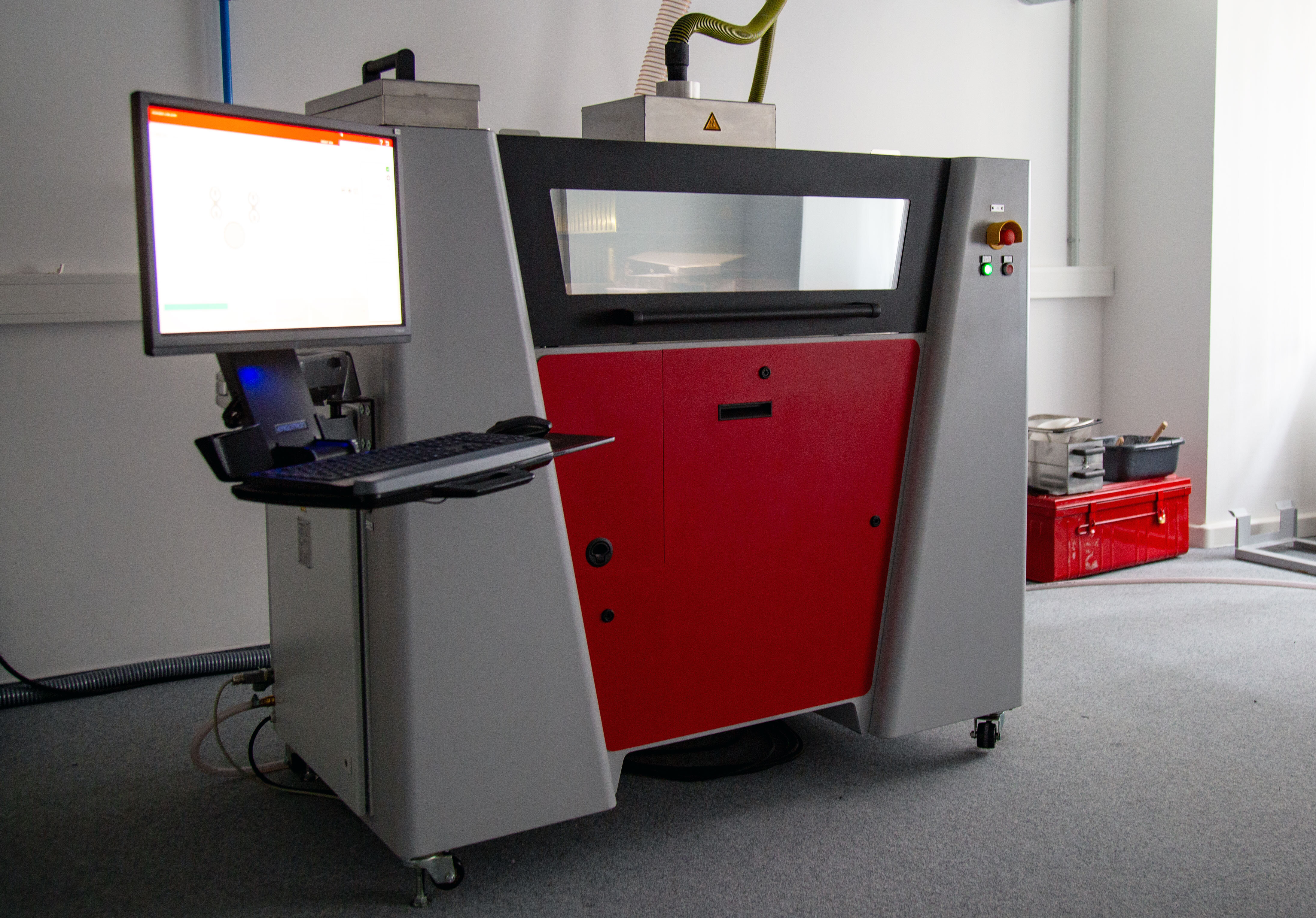

State-of-the-art 3D printer from the DFG's large-scale equipment funding programme put into operation

The new Voxeljet VX200 HSS 3D printer is one of the world's most flexible research platforms for polymer 3D printing. As an open system with freely configurable printing parameters, comprehensive process data access and integrated analysis tools, it is suitable for developing new materials and processes. It also enables the fast and flexible production of prototypes and small series components for research purposes.

Multi-material AM

The acquisition of the VX200 HSS is part of the German Research Foundation's (DFG) "Large-scale equipment programme for universities of applied sciences 2023". Under the leadership of Ingo Reinhold, Chair of Coating Processes, and other participating scientists from various faculties, the research infrastructure of HTWK Leipzig in the field of "Multimaterial Additive Manufacturing" (AM) will thus be significantly expanded.

Professorships involved in the research area of multi-material AM:

- Prof. Dr.-Ing. Ingo Reinhold, HTWK Leipzig, Coating Processes

- Prof. Dr.-Ing. Lutz Engisch, HTWK Leipzig, Materials

- Prof. Dr.-Ing. Paul Rosemann, HTWK Leipzig, Materials Engineering

- Faouzi Derbel, HTWK Leipzig, Smart Diagnostics and Online Monitoring

- Prof. Dr rer. nat. Ines Dani, HTWK Leipzig, Generative Manufacturing Technology

Large-scale equipment funding from the DFG

In addition to the new polymer 3D printing system, the DFG's large-scale equipment funding includes two other research devices that make it possible to map the entire process chain - from material characterisation to development and component testing. Firstly, HTWK Leipzig received a powder clamp including a climate chamber on a precision rheometer. This enables researchers to determine the flow properties of powders in a controlled temperature and humidity environment. This enables them, for example, to optimise powder application in 3D printing and develop functional material composites and components. The third device from the grant - a 3D printer for medical applications - is expected to go into operation at the beginning of November.

"The research infrastructure at HTWK Leipzig is open to all researchers at the university and its partners. It enables the development of unique material combinations through integrated manufacturing processes in order to realise new smart materials and components with integrated functions - such as different mechanical, electrical or biological properties - in a single production step," emphasises Reinhold.